Mẹo Hướng dẫn The idea of is a form of innovation that constantly seeks ways to improve business 2022

Lê Bình Nguyên đang tìm kiếm từ khóa The idea of is a form of innovation that constantly seeks ways to improve business được Cập Nhật vào lúc : 2022-11-26 23:22:05 . Với phương châm chia sẻ Kinh Nghiệm Hướng dẫn trong nội dung bài viết một cách Chi Tiết Mới Nhất. Nếu sau khi Read tài liệu vẫn ko hiểu thì hoàn toàn có thể lại Comment ở cuối bài để Mình lý giải và hướng dẫn lại nha.Chapter 4: Process Innovation

After reading this chapter, you should be able to do the following:

Nội dung chính Show- Chapter 4: Process Innovation Business Process ImprovementTypes of Business ProcessesBusiness Process RequirementsCow Path TheoryProcess Improvement StepsMeasure the Right ThingsImplement a Process Improvement PlanTools and Techniques for Improving ProcessesProcess Improvement MethodologiesWhat is a form of innovation that constantly seeks ways to improve business processes and add value to products and services?Is a sustaining innovation is one that initially provides a lower level of performance than the marketplace has grown to accept?Which concept best describes an agreement between two or more companies that involves the joint production and distribution of goods and services?Is the primary goal of any organization?

Business Process Improvement

Process innovation is probably the least attractive form of innovation. It is the combination of facilities, skills, and technologies used to produce, deliver, and support a product or provide a service. There are many ways business processes can be designed or improved. Process innovation can include changes in the equipment and technology used in manufacturing (including the software used in product design and development), improvement in the tools, techniques, and software solutions used to help in the supply chain and delivery system, changes in the tools used to sell and maintain goods, as well as methods used for accounting and customer service.[1]

Good business processes enable companies to satisfy both customers and employees. Good business processes can drive reliable and consistent results and support company growth. A is a sequence of steps progressing toward a business goal. This sequence of steps can be clearly depicted using a flowchart and may also be referred to as a business method. Developing and implementing business processes can help a company improve efficiency, consistency, and quality. It can also reduce costs and risks. Business processes occur all organizational levels and some are visible to customers, while others are not.

Types of Business Processes

: The processes that plan, organize, coordinate and control all the functions of the business.: The processes that constitute the core business of the organization and create the primary value stream.: The processes that support the core processes. They help the business create an environment where the core processes can work better. Examples include accounting and technical support.Often processes are documented and taught to employees. Employees are expected to follow the business processes as the processes support the company brand, function, mission/vision/values/goals, and service objectives. A great example of a company using processes to streamline operations and maintain consistency and quality is McDonald’s fast-food restaurant. McDonald’s operating processes would include taking orders, making food, and serving it to the customers. The processes for making fries, burgers, and pies are each documented and employees are trained on these processes. Machines are used to cook and warm food and timers are used to enable employees to cook each hamburger or Egg McMuffin exactly the same way each time for every customer.

A simple business process might include the steps an employee follows to take a pizza order over the phone or the steps a college registrar’s office takes to enroll a student in a course. More complex processes might include the steps required to purchase new medical equipment for a hospital, the steps a furniture company follows to manufacture their most popular desk or the steps an executive chef takes to prepare a dinner for six customers.

New employees have a good chance of job success once they learn the business processes. Processes in the kitchen a restaurant might utilize ingredients, utensils, cooking equipment, recipes, etc. Processes in an office might utilize computers, software, office space, people, documents, etc. Processes in a paper factory might utilize people, machines, safety equipment and procedures, raw materials such as pulp/paper, etc. Most big companies have hundreds of interconnected business processes. Knowing how to design, manage, and improve business processes gives companies the power to manage and grow the business.

Students may be frustrated when processes are not clearly defined

Students may be frustrated when processes are not clearly definedGood business processes can improve customer satisfaction while missing or badly designed processes can have a negative effect on customer satisfaction. Assume you are a student a college and you wish to add another course to your schedule, which includes paying additional fees. If there is a good process in place, all employees and computer systems you interact with consistently guide you in the same direction in order for you to complete the process of adding and paying for an additional course. If the process is not clearly designed or it is missing, then employees will be confused and may have their own personal way of doing tasks and systems may not be designed for self-service tasks that enable you to add a course to your timetable.

Business Process Requirements

A good business process meets the following requirements. [2]

Provides clear instructionAnswers frequently asked questionsTeaches new thingsMeasures successProvides corrective actionsWhy do bad business processes exist?

Assumptions. Often companies assume they know what customers want. It is important to challenge these assumptions through research and analysis.Ambiguity. Employees are uncertain of the process. Maybe the process needs more clarification.Miscommunication. The process may not be communicated to employees and employees develop their own processes.Misalignment. Advertising and actions are not aligned with the goals of the process.Since processes are interrelated, each process should consider its relationships with other processes. Good business processes always need to be looking forward and require periodic review and revision to keep up with changes in the internal and external business environments. If a company experiences massive growth, will the processes still be effective and efficient? If a process is good supporting 20 customers, does it still work when supporting 200 customers? Some processes cannot be changed significantly due to a lack of availability of technology and tools. Maybe the steps in the process are not the problem, perhaps the company tools and technology need to be improved. Companies need to ensure their processes are built for both present demand and future growth; that processes are scalable.

Lack of a good process can lead to inconsistency, time loss, employee frustration, customer frustration and dissatisfaction, lost revenue, etc. So you can see why it is important to have good processes in place and ensure staff understands these processes and apply them consistently. Without a good business process company growth and success are difficult to achieve.

Not only is it important to have processes but it is also equally important that these processes be effective and efficient in reaching the goal. If the goal is to add a course to your college timetable, then the process and procedures you follow to do that should help you obtain that goal (effective) and should do it in a timely and user-friendly way (efficient). When processes are created with these things in mind, they increase employee effectiveness and efficiency, maintain consistency and quality, and improve customer satisfaction. Customers continue to shop with a business because of reliability in product or service quality, price, design, etc. Employees become good their jobs because they follow the business process they were given. Once good processes are established one business location, the organization can adopt the same processes multiple locations (just like McDonald’s does).

Business Process Requirements

Does the following Amazon.com Seller process meet the following business requirements for processes?

Provides clear instructionAnswers frequently asked questionsTeaches new thingsMeasures successProvides corrective actionsAmazon.com Seller: Print a packing slip process

Use Manage Orders to print a packing slip for each individual order. To print a packing slip for an order:

Click Orders>Manage Orders.In your list of orders, find the order, and then click the Print packing slip button. A print dialog box and your packing slip will appear.In the print dialog box, click OK to print the packing slip.Put the packing slip in the box with the items you are sending, then seal the box.You can reprint a packing slip for an order using these steps any time.

Tip: To print multiple packing slips the same time, select the check box in the upper-left corner of the list, choose Print packing slip for selected orders from the drop-down menu, and then click Go.

Need some help? See more on Seller Central

Cow Path Theory

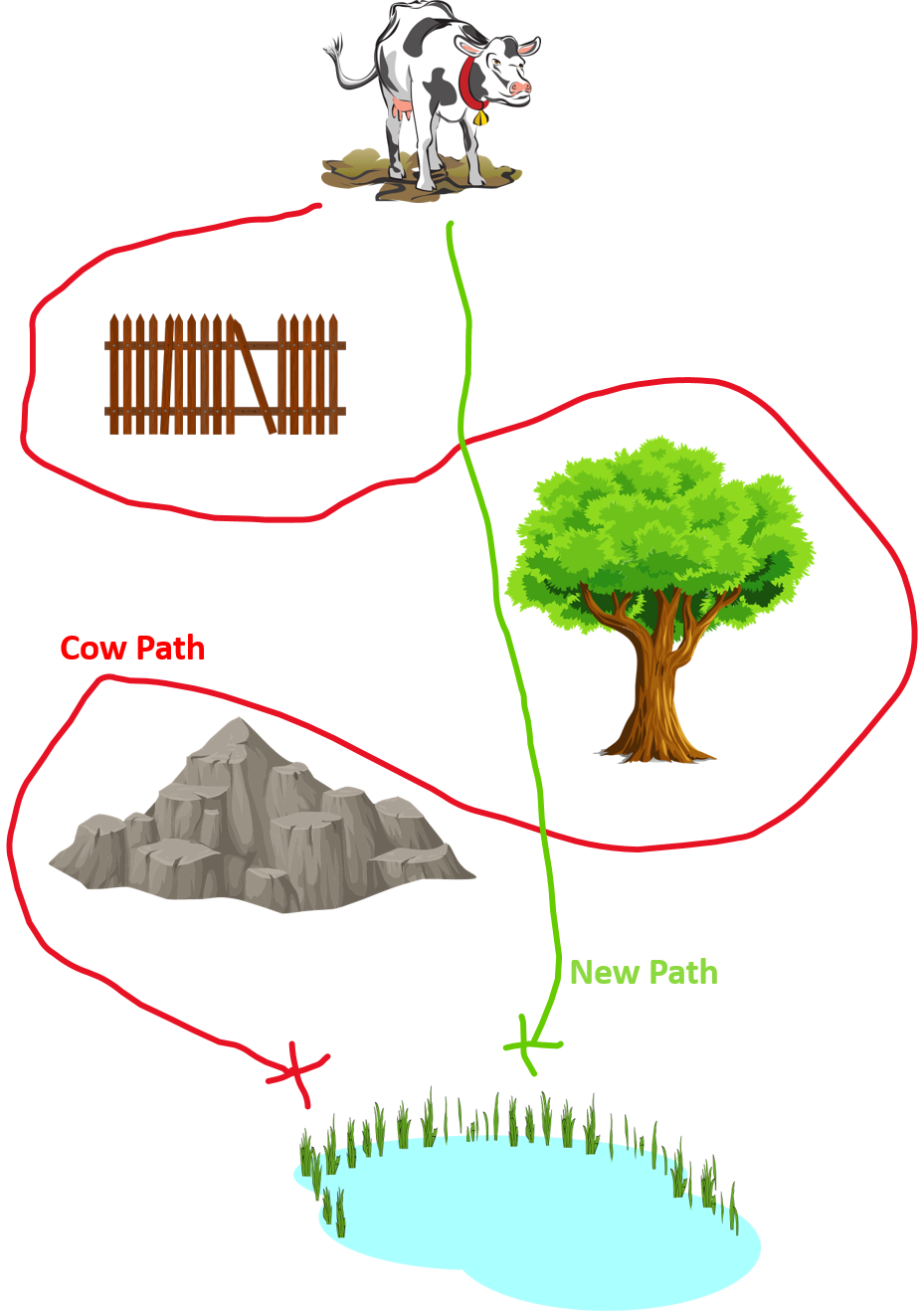

Employees follow the Cow Path when they should be creating a new, more efficient

path

Employees follow the Cow Path when they should be creating a new, more efficient

pathThe is a theory that many organizations have processes they have been following for years and may not notice that these existing processes may no longer be efficient or effective. New employees follow the processes they are told to follow and often without questioning them because new employees don’t want to make a fuss or they feel the process must be right because someone in the company developed it and everyone has been following it for years. Existing employees may continue to follow the old, outdated processes because they are used to them and don’t wish to put in the effort to learn something new, or they don’t feel it is their job to question the processes that have been in place for many years.

Basically, when leaders follow the cow path they are just doing things the way they have always been done without making changes to it. But there are exceptions to this rule. Just because something has always been done a certain way doesn’t mean that it can’t be improved upon or even replaced with something better. Think about how many times you’ve ordered a pizza. It’s not like the process of ordering one has changed much in recent years, but it is now more efficient and effective than ever before. A problem with “cow paths” is that they are so common that no one notices them. The more common something is, the less likely it is that anyone will notice when it’s being done wrong. This means that people who are in a position to change things have little incentive to do so. Cow paths are the result of an unhealthy work environment, where there is no accountability for poor results, and where people are rewarded for failure. Cow paths are usually difficult to detect because they tend to be systemic and non-discriminatory. “Don’t pave the cow path” often refers specifically to businesses that create their own way of doing things in order to innovate and improve on what has been done before. [3]

Process Improvement Steps

The first step in improving any process is setting a goal, then the next step is measuring your progress toward that goal. If there is an existing process in place then you must ask the following questions. Is the business process currently effective in achieving the goal it was designed to do? Is the original goal still the goal to achieve now? Is the original goal efficient? If the answer to any of these questions is “no” then there may be an opportunity to improve the business process.

Watch the “Business Process Improvement Tutorial for Beginners” YouTube video below for an introduction to business process improvement.[4] Transcript for “Business Process Improvement Tutorial for Beginners” Video [PDF–New Tab]. Closed captioning is available on YouTube.

[embed]https://www.youtube.com/watch?v=creyvNYr-e4[/embed]

Before a process can be improved it must be measured so the company will know if the changes have made a difference. For instance, you will want to know if the changes in results were due to something you did, or something else, or just pure chance? There is a 50/50 chance that this year will be better than last year even if you make no changes.[5]

Measure the Right Things

Most process improvements have one or more of the following goals: improve quality, decrease lead time (the time between the initiation and completion of a production process), or decrease costs. Should each goal be measured? Which goal should get priority? It is difficult to achieve all three goals the same time. For example, if a company reduces costs, that may also reduce quality or something else that is important. If time is reduced, that may increase costs. A company can reduce costs by reducing quality, while higher quality products may take a longer time to produce.

Never try to measure just one number without context. For example, if sales revenue has gone up, that seems good, but what else is happening? Was there a sale, were employees reducing prices so they could sell more and gain higher commissions or has something else affected revenue? If customer complaints have increased, first this seems bad, but what if employees have just gotten better listening to customers and reporting complaints, or maybe you implemented an online complaint process that has resulted in customers being able to submit complaints more easily and this has contributed to the rise in complaints. So never measure just one number.

If you find out that your school’s student satisfaction score is 5% worse than another school you must question what “worse” really means, and whether or not 5% is really significant. Maybe your school is better other things and worse one thing. Maybe it is just that this year your school was under construction and that affected student satisfaction negatively, but usually your school has much higher scores. Take measurements as a starting point to asking the question “why?” (Why are these numbers as they are?) This will help you understand the causes of the lower numbers or scores so you can begin to take action.[6]

Implement a Process Improvement Plan

Given how process improvements deliver a range of organizational benefits from better communication to increased profitability, it’s essential to know how to implement a process improvement plan. Listed below are the steps to do so. [7]

Identify the improvement opportunity. Map the current process. Identify the pain points (things that are not working well).Obtain stakeholder buy-in. Clarify stakeholders’ roles and degree of involvement with the process change. Explain the rationale for change.Design the process improvement plan. Determine the changes required to improve the process and decide how you will measure the effectiveness of the changes, evaluate any risks, and identify how the changes will affect the customer experience; for example, introducing a technical solution to streamline the workflow helps, particularly if the solution automates many of the process steps. Transforming processes affects an organization to varying degrees depending on the extent of the changes. If the process improvement is larger than small adjustments affecting a single team, project planning may be needed with a full project plan incorporating the five project management process groups. This includes identifying budgets to cover costs like training and any additional resource requirements needed to execute the changes.Test the changes. Often when designing new processes a company might test in a single department a single location before implementing the changes in all departments multiple locations, or before integrating a new technology system with an old technology system. Take time to test thoroughly and compile measurable results for analysis. Make adjustments as needed, then when you are sure the new process works according to plan then you can roll it out across the organization.Monitor and optimize. Even after thorough testing, process improvements require daily monitoring in the early weeks of a rollout to catch any issues that may have been missed during the test phase. The monitoring should compare the results of the improved process against the goals identified the start of the project. Collect more feedback from stakeholders and continue to optimize until you have met or exceeded all benchmarks for the process.Once a company improves a process, the reality is that it must review the process again in the future. Business goals, market forces, and new technologies evolve, making established processes and procedures inefficient or obsolete. Rather than execute a big project whenever a change is required, most organizations adopt an approach of small, iterative, improvements that happen routinely over time.

Tools and Techniques for Improving Processes

The tools and techniques most commonly used in process improvement are:

- Problem-solving methodology, such as DRIVEProcess mappingProcess flowchartingForce field analysisCause & effect diagramsCEDACBrainstormingPareto analysisStatistical process control (SPC)Control chartsCheck sheetsBlock DiagramsFlowchartsBar chartsScatter diagramsMatrix analysis

Dot plot or tally chartHistograms

The most commonly used business process diagramming tools are Business Process Modeling Notation (BPMN), Data Flow Diagram (DFD), and the Unified Modeling Language (UML). is a graphical method of representing business processes within a business process diagram. BPMN diagrams help the whole team see the flow of the process. For example, the process improvement team may be a cross-functional team consisting of various stakeholders, such as technical personnel who manage Information technology, managers responsible for the process as well as managers of other departments who may be affected by the process change, employees who apply the process, and possibly users (customers, clients, students).

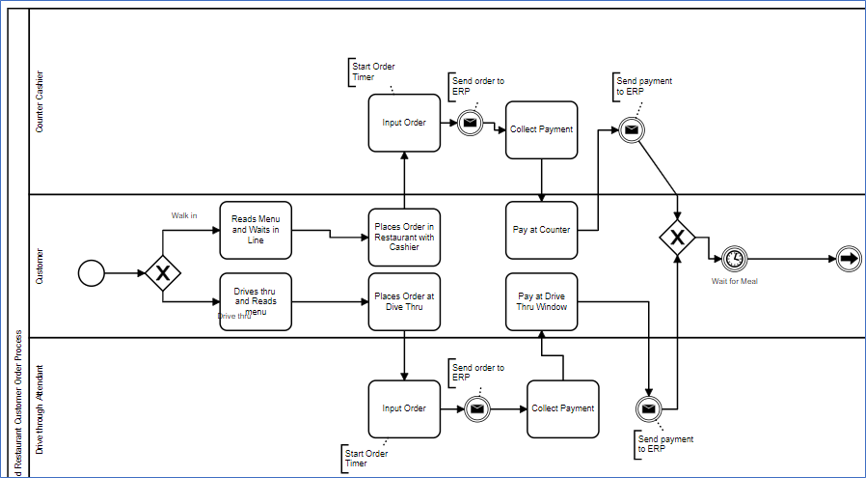

Review the example below of a partial BPMN diagram for a Fast Food Restaurant, Customer Order Process.

Partial BPMN Diagram Fast Food Order Process

Partial BPMN Diagram Fast Food Order ProcessThe BPMN above diagrams the process for the current way the customer order process happens (current state). There are many ways to create this diagram and before starting to diagram the business analyst must first gather information from the stakeholders who implemented, manage, and use the process so as to gain an understanding of who does what, when things get done, how things get done, what is necessary to do and when one step depends upon another (triggers). Once that information has been gathered and analyzed, the business analyst diagrams the process and then gains confirmation and approval from the stakeholders that the diagram does indeed reflect what is currently happening.

After diagramming and gaining an understanding of the current state of the process (the way things are done), the business analyst will analyze the process to determine if improvements could be made. They will question the stakeholders on pain points, what works, what doesn’t and ask them to share their goals for improvements. The business analyst will then diagram a future state process (what the process will be after the improvements are implemented) and again, gain approval for the proposed changes. Then the changes are implemented, first on a small scale or in one location only, to ensure all works as planned. Maybe a few adjustments are made, then the new process is implemented fully.

In the example above you see the partial process you see is diagrammed in a pool called “Fast Food Restaurant Customer Order Process” Each role gets its own lane (swimlane) and each role is an actor (person or system that is part of the process). The customer can be diagrammed in their own pool or within the company pool. If we follow the process flow we see that the process begins with the customer (start symbol), then the customer makes a decision (Xor gateway) to either use the drive-thru or go into the restaurant to eat. After that, the order is placed with the corresponding actor (employee) who then enters the order into the enterprise resource system (ERP) and collects the payment from the customer. The order and the payment details are sent to the ERP (diagrammed in its own lane (swimlane)). After that, the process flow comes back together (convergent gateway) and the customer waits for their meal (timer). What do you think the next step would be? That’s sort of a trick question because many things are happening while the customer waits. There are actually quite a few more steps because the kitchen staff would need to prepare the meal, a staff thành viên would get the drinks/fries, a staff thành viên would package the meal, and a staff thành viên would deliver the order to the customer either the drive-thru or front counter. These tasks may be done by the same staff thành viên or several staff members. You see there are lots of things to think about when diagramming a business process. Learning how to diagram processes is a course in itself, but don’t let that stop you from giving it a try. Check out the chapter exercises below for some ideas.

Process Improvement Methodologies

Process improvement is so important to business success that a number of methodologies have developed over time to address this key concept. Listed below are some of the most common process improvement models.[8]

Six Sigma. One of the most famous process improvement frameworks is Six Sigma. It is a set of techniques designed to make business processes more effective and efficient. In addition to establishing a culture dedicated to continuous process improvement, Six Sigma offers tools and techniques that reduce variance, eliminate defects, and help identify the root causes of errors, allowing organizations to create better products and services for consumers. General Electric, one of the most successful companies implementing Six Sigma, has estimated benefits on the order of $10 billion during the first five years of implementation. GE first began Six Sigma in 1995 after Motorola and Allied Signal blazed the Six Sigma trail. Since then, thousands of companies around the world have discovered the far-reaching benefits of Six Sigma.[9]Kaizen. When applied to the workplace KAIZEN™ means continuing improvement involving everyone – managers and workers alike. This methodology originated in Nhật bản, aims to eliminate all waste from process flows to achieve a high level of efficiency and productivity. Kaizen is known for its team approach where everyone in the organization shares ideas and works together to keep improving every area of a business. If mistakes occur, the goal is to learn from them as part of the cycle of continuous improvement.PDCA (plan-do-check-act). Plan-do-check-act (PDCA) outlines a four-step scientific approach spelled out in its name. First, identify the problem or opportunity and the improvements you hope to achieve. Once a potential solution is identified, test it safely with a small-scale pilot project. Then, analyze if the changes had the desired impact. Finally, you take action based on your data analysis.BPR. Business process re-engineering (BPR) is a framework that tackles process improvement scale. Rather than address a small component of an overall workflow, BPR attempts to address issues and eliminate unnecessary steps by holistically redesigning an entire process from end to end. The changes can be so substantial that a change management plan typically accompanies the use of BPR.[10] Gap Analysis. A gap is a problem, issue or challenge, and could be an opportunity for improvement. Gap analysis compares two different states of something, the current state, and the desired state. It is mainly used to assess where a company or process is today (current state), where it needs to be in the future (future state), and how the gap between current and future states can be closed. Gap analysis is also known as need analysis or needs assessment. You can implement this methodology to confront many types of gaps such as gaps in operational processes, product features, profitability, and labour shortages.Process Mapping. A useful approach that applies careful analysis and a visualization tool to address process issues — or to create a new workflow from scratch — is process mapping. In this method, you create a document that details the steps in a procedure, usually captured in a flowchart. The document allows you to see the entire process and identify areas to change. It then serves as a reference tool for subsequent process changes, or for writing a runbook.[11] A business process is a sequence of steps progressing toward a business goal. This sequence of steps can be clearly depicted using a flowchart and may also be referred to as a business method. Developing and implementing business processes can help a company improve efficiency, consistency, and quality. It can also reduce costs and risks. Business processes occur all organizational levels and some are visible to customers, while others are not.Good business processes can improve customer satisfaction while missing or badly designed processes can have a negative effect on customer satisfaction. A good business process meets the following requirements: Provides clear instruction, Answers frequently asked questions, Teaches new things, Measures success, and Provides corrective actions.Why do bad business processes exist? Because of assumptions, ambiguity, miscommunication, and misalignment.The Cow Path Theory is a theory that many organizations have processes they have been following for years and may not notice that these old processes may no longer be efficient or effective.The first step in improving any process is setting a goal, then the next step is measuring your progress toward that goal. Most process improvements attempt to do one or more of the following: improve quality, decrease lead time (the time between the initiation and completion of a production process), or decrease costs. Never try to measure just one number without context. Ask the question “why” one number is up and another is down. Compare changes in different measurements.Given how process improvements deliver a range of organizational benefits from better communication to increased profitability, it’s essential to know how to implement a process improvement plan. Below are the steps to do so.- Identify the improvement opportunityObtain stakeholder buy-inDesign the

process improvement planTest the changesMonitor and optimize

References

(Note: This list of sources used is NOT in APA citation style instead the auto-footnote and truyền thông citation features of Pressbooks were utilized to cite references throughout the chapter and generate a list the end of the chapter.)

What is a form of innovation that constantly seeks ways to improve business processes and add value to products and services?

Sustaining innovation focuses on creating networks of value and customer satisfaction within the current market. This approach is opposed to disruptive innovation, which creates a new value network. Companies seek to improve product performance each time to reduce defects.Is a sustaining innovation is one that initially provides a lower level of performance than the marketplace has grown to accept?

A sustaining innovation is one that initially provides a lower level of performance than the marketplace has grown to accept. Over time, disruptive innovation tends to become less attractive to users in a new market. Organizations cannot have many value chains.Which concept best describes an agreement between two or more companies that involves the joint production and distribution of goods and services?

A joint venture (JV) is a business arrangement in which two or more parties agree to pool their resources for the purpose of accomplishing a specific task. This task can be a new project or any other business activity.Is the primary goal of any organization?

The primary goal of corporations and businesses is to generate profits. Increasingly, corporate executives and business owners are identifying ways in which their philanthropic contributions can help them meet financial goals. Tải thêm tài liệu liên quan đến nội dung bài viết The idea of is a form of innovation that constantly seeks ways to improve business